Industrial automation company Pakistan for PLC and SCADA integration

JME Energy supports industrial teams with structured control logic, clean SCADA data, and electrical design packs that remain usable after handover. The goal is simple: stable operation today, controlled upgrades tomorrow.

Best starting input single line diagram or drawings plus a short IO estimate.

- Define IO, alarms, and interlocks early to avoid rework later

- Plan screen map and reporting before building tags

- Align FAT and SAT checklist with acceptance criteria

How the work is structured

These are the practical building blocks that keep automation projects stable and maintainable.

What we build and integrate

Services are organized around outcomes: stable operation, clear data, and a handover your team can use.

Industrial automation

PLC logic, IO mapping, alarms, interlocks, commissioning support, retrofit planning.

SCADA and monitoring

Tag database, screens, trends, reports, historian readiness, operator friendly structure.

Electrical design and switchgear

SLD, load schedules, panel GA, wiring schematics, MCC, control panels, ATS and AMF planning.

Process engineering support

Functional descriptions, cause and effect thinking, control strategy notes, optimization oriented inputs.

Audit and recovery

Drawings and backups audit, alarm cleanup, tag cleanup, phased migration planning with controlled downtime.

Deliverables you receive

Instead of vague promises, you get a defined handover pack designed for maintenance and upgrades.

| Area | Typical deliverables | Why it matters |

|---|---|---|

| Automation | IO list, logic map, alarm philosophy notes, backup plan, testing checklist | Faster troubleshooting, safer interlocks, upgrades without rework |

| SCADA | Tag database, screen map, trends set, report fields, user roles notes | Clean data, consistent screens, lower operator confusion |

| Electrical | SLD, load schedule, cable schedule, panel GA, wiring schematics | Clear build quality, easier maintenance, smoother audits |

| Commissioning | FAT and SAT plan, punch list format, commissioning notes, handover checklist | Controlled startup, traceable closure, stability monitoring |

Industries we support

Controls and electrical work that fits process reality, not only drawings.

Power and utilities

Monitoring, operational visibility, stability focus.

Water and wastewater

Pumps, dosing, alarms, reporting structure.

Manufacturing

Lines, machines, interlocks, production dashboards.

Process industries

Cause and effect approach, critical signals planning.

Project workflow

A simple workflow that keeps scope clear and commissioning controlled.

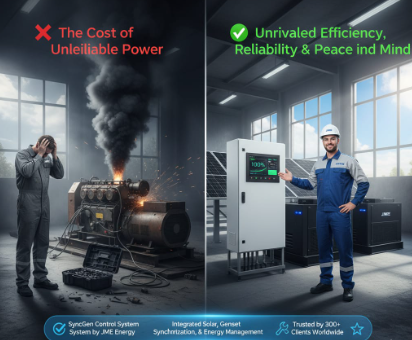

Visual proof blocks

Education style visuals that clarify risk and show what changes when the approach is corrected.

What teams often ask before a site visit

What will be tested

A practical FAT and SAT checklist aligned with acceptance criteria.

What will be handed over

Backups, drawings, tag database notes, and a usable baseline for maintenance.

How downtime stays controlled

Phased cutover planning plus punch list closure and stability monitoring.

Insights Blog

Helpful guides: checklists, troubleshooting structures, documentation templates, SCADA best practices.

FAQ

Do you retrofit existing PLC and SCADA systems?

Yes. We begin with a practical audit of drawings, IO, tags, alarms, and backups, then propose a phased plan that keeps downtime controlled.

Do you support electrical design and switchgear work?

Support can include SLD, load schedules, panel GA, wiring schematics, and integration planning based on site scope and requirements.

What should we share for a fast first response?

Industry, location, PLC brand or current system, approximate IO points, SCADA needs, timeline, plus drawings or panel photos.

Where is your office?

Shadman Plaza, Lahore. Phone 0333 4532840. Email sales@jme-energy.com.

Contact and booking

Office

Shadman Plaza, Lahore

Phone: 0333 4532840

Email: sales@jme-energy.com

For the fastest response, paste the scope template from the hero section.

Lightweight visual

For performance, keep the homepage lightweight. Avoid heavy embeds.